Homemade Propane Burner For A Backyard Foundry

This isn’t a project for everyone. There’s propane, fire, and very hot temperatures. If you have any doubts about your skills, work on honing them and come back another day.

But some people, when they see a metal, they want to melt it. In this case, that metal is aluminum. The easiest way to heat a foundry at home is with charcoal. A well-made charcoal foundry can get upwards of 1000° F, which is plenty hot for making molten aluminum. Honestly, this really is the best way to get started.

After awhile, you might feel like taking it up a notch and making your own propane powered foundry. If you have the skills, it’s a fun project that can be completed in a day. It’s not expensive if you have a lot of pipe and other parts lying around.

If you don’t have the parts, you’ve got a choice to make. Premade propane burners aren’t very expensive, and get you right to working on your foundry. Yes, it’s not the same as building one, but if you are weekend warrior you have to decide if you get more enjoyment from using your forge or foundry, or from building things. If it’s the former, here’s one kit that’s available on Amazon.

- Heavy duty stainless steel high output burner designed, engineered, and manufactured in the united states

- 130,000 BTU rating at 30 PSI pressure

- Adjustable air choke and expansion chamber

- The end of the burner measures 1-3/8" to fit 1-1/2" forge/foundry opening.

If you are still here, there are a few different plans you can use floating around the internet. This one (made in the video by Will Matthews) is based on a design by John Carman. Ideally, go for black iron pipe rather than galvanized. If you do end up with galvanized pipe parts, you’ll need to remove the coating over the course of a few days – otherwise you will be putting yourself at risk of poisoning.

One way to remove the coating from galvanized pipes is to soak them in white vinegar. It takes a few days to work it’s magic, but given enough time you’ll be able to use those parts in the project.

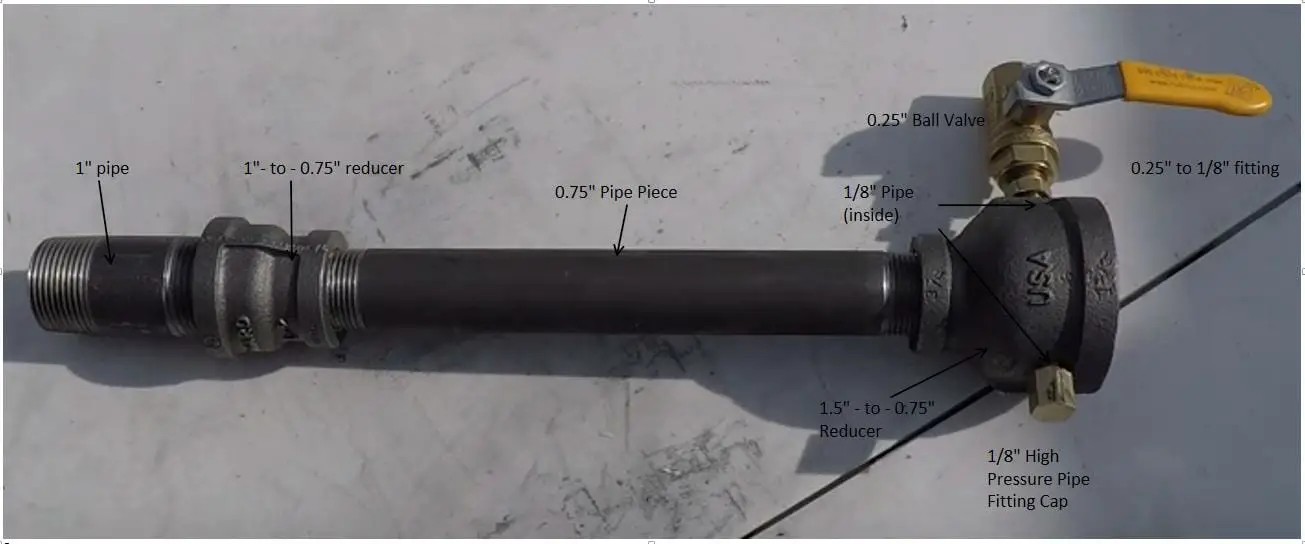

Here’s a part list, and a video showing the steps you need to take in order to complete this project.

Foundry Burner For Those With Welders

While the forge is cool as well, we are really just looking at the burners in this article. All of the different home-made plans have similar designs.

- We need a way to get the propane out of the container safely.

- We need a way to mix air and fuel together.

- We need a way to control how much fuel we are burning (and a way to turn it off)

Forge Burner For Those With Only A Few Tools

Not everyone has a completely-outfitted garage at their disposal. You might not have a welder, or a drill press – sure you’ll get them someday but for now you don’t have access to use them.

Never fear – this can be a very simple build.

There’s no welding required here – just drilling of the 1.5″ reducer to fit the 1/8″ pipe through, and drilling of the 1/8″ pipe with a Wire Gauge 60 drill bit. That takes some patience because of how thin of a bit you are dealing with, but nothing one can’t handle.

Here’s a short video on how it’s put together. If you end up making either of these burners, please let us know in the comments.

Prices and availability are accurate as of 2024-09-14 at 09:44 CST - Details